|

Henan Sanxiong Heavy Industries CO., LTD

|

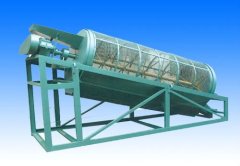

low cost drum screen for brick making

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. low noise

2. made of good steel, long service life

3. wide application

Drum Screen is applied in process of particles grading. Drum screen is suitable for screeningand classifying gravel, clay, mountain meal, sand, lump coal, coal dust,coal washing,lump,powder substance, etc. Drum screen is widely used inquarry, coal industry, chemical, mineral-selecting industry, metallurgy,construction and other industries .

A small red drum screen in factory:

Main Technical Parameters of Drum Screen | |||||

Model | Capacity(Myriad T/Year) | Capacity(T/H) | Sieve Dia.(mm) | Length (m) | Power (kw) |

GTS-3 | 3 | 10.4 | Φ1200 | 3.5 | 4 |

GTS-5 | 5 | 13.8 | Φ1200 | 4 | 5.5 |

GTS-10 | 10 | 27.8 | Φ1400 | 5 | 7.5 |

GTS-15 | 15 | 47.7 | Φ1500 | 6 | 11 |

Drum screen consists of motor, decelerator, rotordrive, chassis, seal cap, inlet and outlet.

A small red drum screen in factory:

How does drum screen work?

Afterthe materials beingfed into the drum, they are lifted up by therotation and aerated as they fall back down. This action is repeatedwith each revolution along the length of the drum. The final materialspass through the screen opening while the larger materials tumbletowards its eventual exit at the rear of the drum.

A small red drum screen in customer's fields:

Drum screen features:

installed on a central axle trailer or on a semi-trailer

- well equipped standard version

- drum rpm adjustable via frequency converter

- welded spirals guarantee high screening capacities and a dosed feed

- in case of volume reduction and screening of fines optimal results in combination with the HAAS Primary Crusher, HDWV

- screening capacities of 10 - 300 m³/h

- drum easily to be changed

- installation possible directly above a silo

- wide, galvanized evacuation trough conveyors

- options: FE-Separation, wind sifting for separation of the light fraction, extension of the infeed bunker, etc.

- well equipped standard version

- drum rpm adjustable via frequency converter

- welded spirals guarantee high screening capacities and a dosed feed

- in case of volume reduction and screening of fines optimal results in combination with the HAAS Primary Crusher, HDWV

- screening capacities of 10 - 300 m³/h

- drum easily to be changed

- installation possible directly above a silo

- wide, galvanized evacuation trough conveyors

- options: FE-Separation, wind sifting for separation of the light fraction, extension of the infeed bunker, etc.

Drum screen, A good machine for grading and screening materials!

Related Search

Brick Making

Brick Making Machine

Cement Brick Making Machine

Automatic Brick Making Machines

Concrete Brick Making Machine

Clay Brick Making Machine

More>>