|

Henan Sanxiong Heavy Industries CO., LTD

|

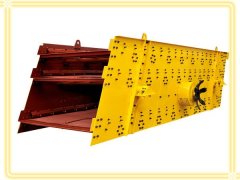

cheap stone vibrating feeder

| Price: | 3200.0~16000.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. low manufacturing cost

2. good steel, durable

3. low noise

Stone vibrating feeder, usually used in sand making production line, mineral processing production line, etc

stone vibrating feeder in workshop:

stone vibrating feeder technical parameter:

Model | Funnel size (mm) | Max Feed size (mm) | Capacity (t/h) | Power (kw) | Weight (T) | Dimension (LxWxH) (mm) |

GZD- 850X3000 | 850X3000 | 400 | 80-120 | 7.5 | 3895 | 3110X1800 X1600 |

GZD- 960X3800 | 960X3800 | 500 | 120-210 | 11-15 | 3980 | 3850X1950 X1630 |

GZD- 1100X4200 | 1100X4200 | 580 | 200-430 | 11-15 | 4170 | 4400X2050 X1660 |

GZD- 1100X4900 | 1100X4900 | 580 | 280-500 | 15-18.5 | 4520 | 5200X2050 X1700 |

GZD- 1300X4900 | 1300X4900 | 650 | 450-600 | 18.5-22 | 5200 | 5200X2350 X1750 |

stone vibrating feeder in workshop:

Stone vibrating feeder installation, debugging and maintenance:

1.Usingbatchingand rationing, to ensure the stable feeding evenly, should behorizontal installation to prevent materials automatic flow , As generalcontinuously feeding, recommendation declinator 15° installment.

2.Installment feeding engines should leave leeway is not smaller than 20millimeters to hover the gap, Transverse should be level, suspensiongearuses soft connection,

3. Before empty try, All the bolts should befixed again ,especially for foundation bolt, should be fixed once moreafter working three to five hours.

4. Two vibration motors must pin forward during test.

5.when vibrating, should often check the amplitude during working,current and noise's stability, stop the feeder when abnormal condition.

2.Installment feeding engines should leave leeway is not smaller than 20millimeters to hover the gap, Transverse should be level, suspensiongearuses soft connection,

3. Before empty try, All the bolts should befixed again ,especially for foundation bolt, should be fixed once moreafter working three to five hours.

4. Two vibration motors must pin forward during test.

5.when vibrating, should often check the amplitude during working,current and noise's stability, stop the feeder when abnormal condition.

6. Charging lubricant for Motor bearing every two months, High temperature season, should Charging lubricant once a month.

stone vibrating feeder in workshop:

stone vibrating feeder, vibrating feeder for stone!